روبوت ممر 5 محاور عالي الدقة للتعامل مع المكونات الحساسة - أتمتة التحميل/التفريغ باستخدام الحاسوب

تفاصيل المنتج:

| مكان المنشأ: | الصين |

| اسم العلامة التجارية: | OSMANUV |

| إصدار الشهادات: | ISO9001 |

| رقم الموديل: | OSM-GR-1320 |

شروط الدفع والشحن:

| الحد الأدنى لكمية: | 1 مجموعة |

|---|---|

| الأسعار: | قابل للتفاوض |

| تفاصيل التغليف: | صندوق خشبي |

| وقت التسليم: | 30 ~ 45 يومًا |

| شروط الدفع: | تي/تي |

| القدرة على العرض: | التفاوض |

|

معلومات تفصيلية |

|||

| مادة الإطار: | الفولاذ المقاوم للصدأ / الكربون الصلب | تطبيق: | مناولة المواد والتغليف وخطوط التجميع |

|---|---|---|---|

| نقل الاتجاه: | من اليسار إلى اليمين | مادة الحزام: | بولي كلوريد الفينيل، المطاط، بو |

| مواد الطباعة: | جيش التحرير الشعبى الصينى، ABS | حسب الطلب: | نعم |

| عرض الورق الصافي: | 1320 ملم | مادة: | الفولاذ المقاوم للصدأ والبلاستيك |

| إبراز: | روبوت ممر 5 محاور لأتمتة التحكم الرقمي الحاسوبي,روبوت دقيق للتعامل مع المكونات الحساسة,أتمتة التحميل/التفريغ باستخدام الحاسوب مع سير ناقل,precision robot for sensitive component handling,CNC load/unload automation with conveyor belt |

||

منتوج وصف

روبوت ممر 5 محاور عالي الدقة للتعامل مع المكونات الحساسة - أتمتة التحميل/التفريغ باستخدام الحاسوب

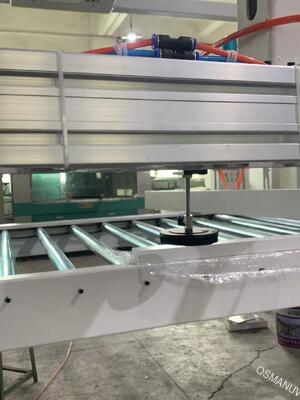

تكوين خط الإنتاج

نظام ممر عالي الدقة مبني من مواد توليد الجسيمات الدنيا، ومحركات خطية تعمل بالسيرفو، وذراع روبوت بـ 5 محاور مثبت على المحور Z، ونظام رؤية للتوجيه، ونظام تحكم متوافق مع بروتوكولات الغرف النظيفة.

وصف المنتج

تم تصميم روبوت الممر ذو الـ 5 محاور عالي الدقة للتعامل مع المكونات الدقيقة وعالية القيمة في صناعات مثل الإلكترونيات والأجهزة الطبية والبصريات. يوفر دقة على مستوى الميكرون ويتوفر في إصدارات متوافقة مع الغرف النظيفة، مما يضمن معالجة لطيفة ودقيقة دون تلويث المنتجات الحساسة.

المعايير الفنية

| المعلمة | المواصفات |

|---|---|

| الموديل | سلسلة GPR-P |

| محور الحركة | 5 محاور (X، Y، Z، R، إمالة) |

| تكرار تحديد المواقع | ± 0.02 مم |

| تقنية القيادة | محركات خطية عالية الأداء |

| تصنيف الغرفة النظيفة | اختياري ISO Class 5 (ISO 14644-1) |

| نظام التحكم | وحدة تحكم حركة متقدمة مع تكامل الرؤية |

| سعة الحمولة | حتى 10 كجم (قابلة للتخصيص) |

| مادة القضيب الدليلي | الفولاذ المقاوم للصدأ أو السيراميك (قابلة للتخصيص) |

التطبيق

-

تحميل/تفريغ الرقائق ولوحات الدوائر المطبوعة والمكونات الدقيقة.

-

التجميع الآلي للأجهزة الطبية والأدوات البصرية.

-

محطات الاختبار والفحص الدقيقة.

التخصيص

هذا النظام قابل للتخصيص للغاية للتطبيقات المتقدمة. يمكننا س: ما الفرق بين التكرار والدقة؟ مستوى الدقة، وشهادة الغرفة النظيفة، وتكامل أنظمة الرؤية المحددة، وتطوير أدوات إمساك متخصصة ذات تلامس ناعم للأجزاء الهشة.الميزةدقة دون المليمتر:

تمكن المحركات الخطية وأجهزة التشفير عالية الدقة من تحقيق دقة لا مثيل لها.

-

متوافق مع الغرف النظيفة: مصمم لتلبية معايير النظافة الصارمة.

-

توجيه الرؤية المتقدم: يضمن الالتقاط والوضع بدقة حتى مع اختلاف موضع المنتج.

-

المناولة اللطيفة: يمنع التحكم في القوة القابل للبرمجة تلف العناصر الدقيقة.

-

تسجيل البيانات: يتتبع بيانات العملية لتتبع كامل وإحصائيات مراقبة العمليات.

-

الدعم والخدماتنحن نقدم دعمًا هندسيًا واسع النطاق للتطبيقات، ومعايرة في الموقع، ووثائق التحقق (IQ/OQ)، وإجراءات تركيب متخصصة للغرف النظيفة.

التعبئة والشحن

يتم شحن النظام في كيس غرفة نظيفة، يتم تطهيره بغاز خامل، وتأمينه في صندوق مصمم خصيصًا لمنع التلوث والتلف أثناء النقل.

الأسئلة الشائعة

س: هل يمكن لهذا الروبوت التعامل مع الأجزاء ذات التفاوت في الموضع؟

ج: نعم، يمكن لنظام الرؤية المتكامل تحديد موقع الأجزاء والتعويض عن أخطاء الموضع، وهي ميزة

-

قابلة للتخصيص

-

أساسية للتطبيقات الواقعية.س: ما الفرق بين التكرار والدقة؟ج: التكرار هو مدى اتساقه في العودة إلى الموضع الذي تم تعليمه. الدقة هي مدى اقترابه من الموضع الحقيقي المطلوب. تتفوق نماذجنا الدقيقة في كليهما، مع مواصفات يمكن

-

-

تخصيصها

-

لتلبية احتياجاتك.ج: نعم، يمكننا توفير حزمة تحقق من الصحة

-

-

مخصصة

-

تدعم تأهيل التثبيت (IQ) وتأهيل التشغيل (OQ) للصناعات الخاضعة للتنظيم.

-